|

|

|

|

|

|

| PRODUCT INDEX > CAST BRONZE SIGNAGE | . |

|

|

|

| Options ----------------> | Sizes | Background Textures | Letter Styles |

| (Click to jump to a | Materials | Background Colors | Mounting Method |

| particular section) | Borders | Finishes | Artwork Requirements |

Please contact us for pricing

| Sizes |

Standard sites for cast name strips and plaques are shown below. Custom shapes and sizes up to 120" x 120" cast in one piece are available. Larger sizes can be cast in smaller sections and fabricated.

Section 1 - Nameplates & Small Cast Plaques

|

Size (in inches) |

Size (in inches) |

Size (in inches) |

Size (in inches) |

| 6 x 1/2 | 9 x 1/2 | 12 x 2 | 18 x 4 |

| 6 x 1 | 9 x 1 | 12 x 2-1/2 | 18 x 6 |

| 6 x 2 | 9 x 2 | 12 x 3 | 18 x 8 |

| 6 x 3 | 9 x 3 | 12 x 4 | 20 x 2 |

| 6 x 4 | 9 x 4 | 12 x 5 | 20 x 4 |

| 6 x 6 | 9 x 5 | 12 x 6 | 20 x 6 |

| 7 x 1/2 | 9 x 6 | 12 x 8 | 20 x 8 |

| 7 x 1 | 9 x 9 | 14 x 2 | 24 x 4 |

| 8 x 1/2 | 10 x 2 | 14 x 4 | 24 x 6 |

| 8 x 1 | 10 x 2-1/2 | 14 x 6 | 24 x 8 |

| 8 x 2 | 10 x 3 | 14 x 8 | 30 x 4 |

| 8 x 3 | 10 x 4 | 16 x 2 | 30 x 6 |

| 8 x 4 | 10 x 5 | 16 x 4 | 30 x 8 |

| 8 x 5 | 10 x 6 | 16 x 6 | 36 x 4 |

| 8 x 6 | 10 x 8 | 16 x 8 | 36 x 6 |

| 10 x 10 | 18 x 2 | 36 x 8 |

|

Size (in inches) |

Size (in inches) |

Size (in inches) |

| 12 x 10 | 20 x 10 | 30 x 12 |

| 12 x 12 | 20 x 12 | 30 x 18 |

| 14 x 10 | 20 x 14 | 30 x 20 |

| 14 x 12 | 20 x 16 | 30 x 24 |

| 14 x 14 | 20 x 18 | 30 x 30 |

| 15 x 10 | 20 x 20 | 36 x 20 |

| 15 x 12 | 24 x 10 | 36 x 24 |

| 16 x 10 | 24 x 12 | 36 x 30 |

| 16 x 12 | 24 x 16 | 36 x 36 |

| 16 x 16 | 24 x 18 | 36 x 42 |

| 18 x 10 | 24 x 20 | 36 x 48 |

| 18 x 12 | 24 x 24 | |

| 18 x 15 | 26 x 34 | |

| 18 x 18 | 28 x 18 | |

| 28 x 40 |

Section 3 - Round Cast Plaques

| Diameter | Diameter | Diameter |

| 12" | 24" | 36" |

| 18" | 30" | 48" |

Helpful Hints

Cast plaques are manufactured using sand molds in our state-of-the-art foundry from raw ingot alloyed in the following materials:

|

Cast Bronze Equivalent to Copper Development Association Alloy C92200; 88% copper, 6% tin, 4% zinc, 2% lead. |

|

Cast Aluminum Cast from Aluminum Association Association Alloy Designation C443.2. |

Helpful Hints

| Borders |

The border on a cast plaque is cast integral with the plaque and is generally highlighted by either a stroke-sander, a buffing wheel or hand-rubbed to provide a pleasing contrast with the background finish.

Standard Borders

These consist of flat borders and are available at no extra cost on all standard

sizes. Some designs are not practical on small name strips under 3" in height.

| Straight Edge (SE) (no border) |

Single Line (SL) |

Bevel Edge (BE) |

Single Line Bevel Edge (SLBE) |

Double Line (DL) |

|

|

|

|

|

Ornamental Borders

Decorative borders based on classic designs are available at additional cost on

most standard sizes. These borders are dimensionally sculpted and hand finished.

Because these are custom made, often they are used in combination with an

unusual shaped or sized plaque.

| Egg & Dart (with optional corner detail) 5/8", 3/4", 7/8", 1" |

Beaded Bevel 1/4" |

Lamb's Tongue 3/4", 7/8", 1", 1-1/8" |

Ivy Leaf 3/8", 1/2", 7/8" |

Oak Leaf 1" |

Laurel 7/8", 1", 1-1/8", 1-1/4" |

|

|

|

|

|

|

| Reed & Ribbon 3/4" |

Ogee (inside curve) 1/2" minimum |

Water Leaf (with optional corner detail) 1" |

Union 3/4", 7/8", 1" |

||

|

|

|

|

Flat Decorative Borders

These borders are produced from black & white line art. Borders are raised the

same height as the plaque lettering and are highlighted to match the raised

copy. A few standard examples are shown; others can be easily created from

artwork.

| Adam (1-1/2" minimum width) |  |

| Floral Stencil (5/8"minimum width) |  |

| Greek Key (5/8"minimum width) |  |

Helpful Hints

All plaques are manufactured with a background texture. When none is specified, leatherette will be used.

Leatherette |

Pebbled limited to 30" x 40") |

Travertine |

Sculptured |

Helpful Hints

The background of most cast plaques is painted to provide a pleasing contrast to the highlighted areas. Both cast bronze and aluminum plaques may be painted with standard or optional (extra cost) finishes pictured below. Custom-matched painted colors can also be provided. Additionally, natural chemical patinas and simulated painted patinas are available on bronze plaques.

Standard Painted Colors

|

|

|

|

|

|

|

|

| Light Oxide Stain | Dark Oxide Stain | Dark Green | Natural Sandblast (Bronze) | Natural Sandblast (Aluminum) | Metallic Grey | Black | M38 Green |

|

|

|

|

|

|

|

|

| M102 Orange | M107 Red | M115 Dark Red | M118 Maroon | M40 Golden Bronze | M71 Cream | M58 Ivory | M65 Beige |

|

|

|

|

|

|

|

|

| M20 Light Blue | M25 Medium Blue | M28 Dark Blue | M70 Dark Brown | M5 Light Grey | M8 Medium Grey | M9 Dark Grey |

Hand Rubbed Finishes (optional)

|

|

|

Antique (on Bronze) |

Pewter (on aluminum) |

Simulated Patina Colors (optional)

|

|

|

|

|

|

|

|

| Anatole Green | Alta Mesa Green | Turquoise | Teal Blue | Twilight Blue | Sea Green | Moss Green |

Chemical Patina Finishes (optional)

The patina finishes are created by applying chemicals and heat to the bronze surfaces. Once the desired color is achieved, the raised areas are highlighted

and a clear protective coating is applied to inhibit further chemical reaction.

|

|

|

|

|

|

| Sea Green | Teal Blue | Moss Green | Turquoise | Amber | Burnt Sienna |

Helpful Hints

Once the background of the plaque has been painted, the surface areas are highlighted by sanding (flat areas) or buffing (sculpted areas). To inhibit natural oxidization, a clear, protective coating is then applied.

Highlighting Finishes

|

Satin Bronze The Natural metal color with subtle horizontal grain lines meets NAAMM finish designation M33-C11-060. |

|

Satin Aluminum The natural metal color with subtle horizontal grain lines. Meets NAAMM finish designation AA-M33-C11-R10. |

|

Polished Bronze The natural metal color buffed to a high gloss, obtained by polishing with successively finer abrasives, then buffing with fine buffing compound. Meets NAAMM finish designation M42-M22-C10-060. |

|

Chrome Plated Bronze The raised surface of the bronze plaque is polished to meet the polished bronze specifications. The background of the plaque remains in its "natural sandblast" state, providing contrast with the polished raised surface. The entire plaque is then electro-plated using a standard commercial copper/nickel/chrome plating process. |

Protective Finishes

In order to protect the natural, highlighted finish of a cast bronze or a

aluminum plaque, two options are available:

Clear Protective Lacquer

Providing a low gloss appearance, this clear coating was developed

to help ensure many years of carefree maintenance. This option should be

selected when matching older plaques or when a lower gloss look is desired

(particularly for interior applications.)

Diamond Shield® Protective Coating

Chemists developed this 2-part coating

for protection in the harshest environments. Diamond Shield® can be

factory-applied only and provides maximum protection. This coating is applied

with a heavier thickness than our clear protective lacquer and is available in a

high gloss version only. Diamond Shield® is particularly effective in harsh,

exterior environments, where plaques are exposed to salt, pollution and weather.

Helpful Hints

Cast plaques are photographically reproduced from typeset letter styles. As a result of this technology, practically any letter style (or artwork) can be incorporated into a cast plaque.

Listed below are 36 standard letter styles most commonly used on plaques. Other fonts are available upon request through our graphics library.

Custom letter styles may also be provided for cast plaques. Before submitting artwork, review the guidelines in the Artwork section.

Raised vs Recessed Graphics

The casting process creates plaques with 2 levels of graphics - raised and recessed. Graphic images are raised .100" from the background texture.

|

Recessed Letters |

Raised Letters |

Letters can be recessed on a cast plaque if the stroke of the letters is at least 1/8" at all points or serifs.

|

Example: Narrowest point on serif must be at least 1/8" |

These plaques pictured below were made from the same artwork but the raised and recessed areas were interpreted differently.

|

|

|

|

Standard Letter styles

|

|

|

A variety of standard as well as special mounting methods are available to suit virtually any installation.

Standard Mounting Methods

Bosses and Studs (BS)

|

Bosses (extra pads) are cast onto the back of the plaque. These are drilled

and tapped to accept a threaded stud.

Flat-backed plates (generally, smaller sizes) are drilled & tapped for studs without bosses on the back. |

Recommended Uses

For concealed, permanent mounting to:

- Brick walls

- Stone walls

- Masonry surfaces

Installation

Drill holes in the mounting surface slightly larger than the diameter of the studs. Fill mounting holes with silicone, epoxy or quickset cement. Set into the holes, and allow the adhesive to cure.

Rosettes and Toggles (RT)

|

Holes are drilled through the face of the plaque for toggle bolts. Toggle bolts are threaded machine screws 4" to 6" long with spring-loaded butterflies that fold up and pass through wall holes. |

Recommended Uses

For semi-permanent mounting to:

- Hollow tile

- Cement block

- Drywall

- Wood paneling over stud construction

Installation

Using the plaque holes as a template, drill holes through the wall large enough to accommodate the butterfly assembly. Insert each machine screw through the plaque and screw on each butterfly. Fold the butterfly assemblies and insert them through holes until wings spring open inside the hollow wall.Pull back on each screw head to press the butterfly against the inside wall. Turn each machine screw, first by hand, then with a screwdriver.

If rosette covers are provided, screw rosettes into the toggle bolt heads.

Rosettes, Machine Screws

and Expansion Sleeves (RM)

|

Holes are drilled through the face of the plaque for machine screws. Each metal expansion sleeve (or lead anchor) has a threaded interior to house a machine screw. The lead anchor will expand when a screw is inserted and tightened. |

Recommended Uses

For semi-permanent mounting to:

- Brick walls

- Stone walls

- Masonry surfaces

Installation

Using the plaque holes as a template, drill holes into the wall large enough to accept the lead anchor. Drill deep enough so the fully driven screw won't strike the back of the hole.Insert expansion sleeves into holes, threaded cones first. Using a metal setting tool, strike tool with hammer to drive sleeve into each hole. Insert each machine screw through the plaque and tighten screws into expansion sleeves with a screwdriver.

If rosette covers are provided, screw rosettes into the machine screw heads.

Wood Screws (WS)

|

Holes are drilled through the plaque and countersunk to accept a flat head wood screw. Larger sized wood screws, #14 or #16, have the heads drilled and tapped to accept a rosette cover. |

Recommended Uses

For semi-permanent mounting to:

- Wood walls

- Plaster walls (small plates only)

Installation

Using plaque holes as a template, drill wall holes. Insert wood screws through the plaque holes and tighten screws with a screwdriver.If rosette covers are provided, screw rosettes into the wood screw head.

Optional Mounting Methods

Invisible Frame (IF)

|

Angle clips are provided to mount to the wall with standard fasteners, such as toggle bolts, wood screws or machine screws & expansion sleeves. |

The cast plaque is then attached to these angle clips with flat head machine screws. These machine screws run through the top and bottom return edges of the plaque.

Invisible Frame mounts require the depth of the plaque to be a minimum of 1-1/4", to accommodate the angle clips.

Recommended uses

For concealed mounting when

- Plaque may need to be relocated in the future

- Plaque size is a minimum of 12" x 10"

Brass Rod Stake Mount

Special mounting brackets are cast in place on the back of the casting to

accommodate a 24" x 3/8" threaded brass rod. Stake mounts can be angled 45° for

positioning plaque at an angle.

|

Recommended uses

|

Garden Stake

Bronze stake measuring 24" x 1-1/2" and attached to back of plaque with 10-24

machine screws. Stake is painted to match the background color of the plaque.

|

Recommended uses

|

Integral Post Cap Mount

A post cap is a decorative sleeve cast integral with the bottom of a plaque to

mount onto a round post. Post caps are available in several standard designs to

accommodate 1-1/2" or 2" diameter post mounts.

|

Recommended uses

|

Curved

Plaques

We can roll a bronze or aluminum plaque to fit a curved wall installation.

Provide the diameter, radius or circumference of the curved surface.

Parameters for usage

- Maximum size of plaque 96" wide x 60" high

- Flat backed castings, 1/4" or 3/8" thick

- Border design must be flat (Straight Edge, Single Line or Double Line)

- Mounting holes through the face are highly recommended.

Rosettes

Rosettes are decorative elements used to cover the screw heads on a plaque

installation. Rosettes can also be used with other materials to accent architectural décor.

All rosettes (except R77) are available in cast bronze, brass or aluminum. Rosettes marked with an asterisk (*) are standard---all others are available as an option.

|

|

|

|

|

*R2 5/8" *R5 1-1/8" |

*R32 7/8" | *R77 5/8" |

*R74 11/16" *R16 1-1/8" |

|

|

|

|

| R60 2-1/2" | RH 2" | R99 1-3/8" | |

|

|

|

|

| R69 1-1/2" | R123 1" |

R2140 1-3/8" |

R95 1-3/8" |

|

|

|

|

| 1" Star with R16 1-1/8" | 1-3/8" Star |

R57 9/16" R54 11/16" |

R48 1" |

|

|

|

*indicates standard rosette |

| R4 7/8" | R1184 7/8" | R1023 5/8" | |

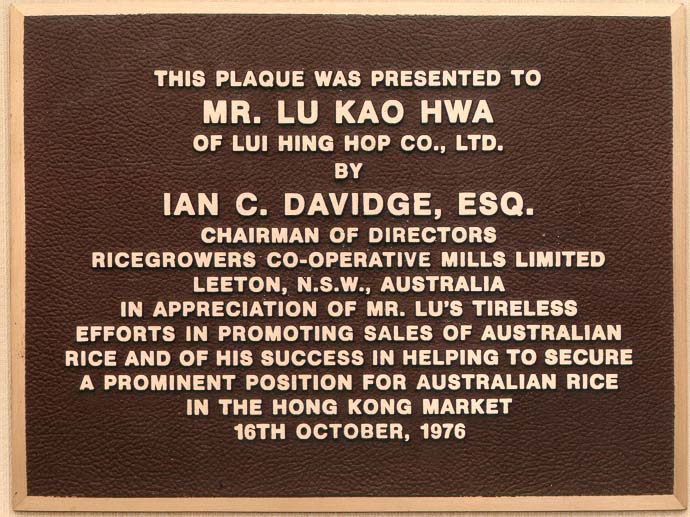

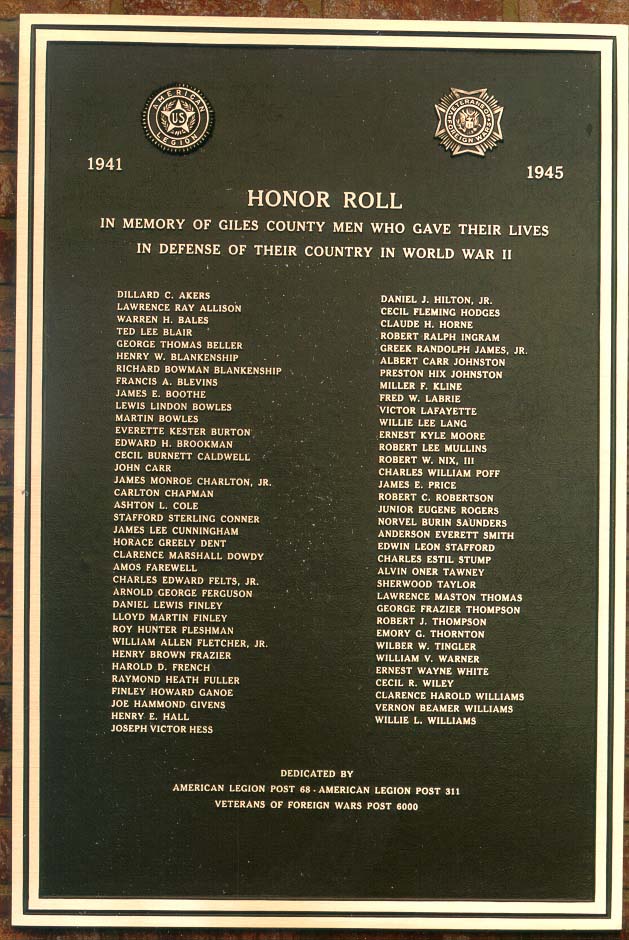

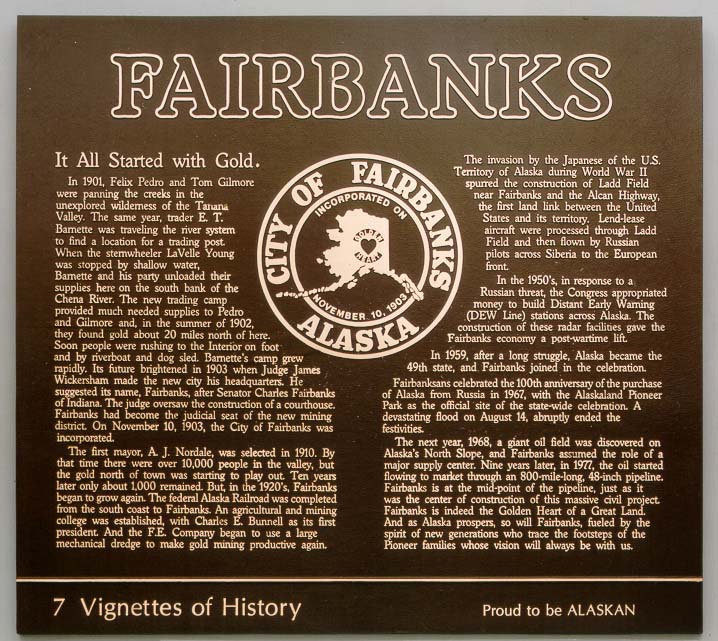

Recent jobs: (click pic for larger image)

|

|

FOR PERSONAL SERVICE, YOU CAN CALL CLASSIC DESIGN AWARDS AT 847-470-0855.

Copyright © 2000-2020 Classic Design Awards, Inc.. All rights reserved. Prices subject to change without notice. Revised:

08/24/20